Key Takeaways

In summary, AI-powered safety systems reduce construction incidents by 60%, improve PPE compliance from 23% to 94%, and detect violations in 8 seconds instead of hours. The typical ROI payback period is 4-8 months for major projects.

- Computer vision AI monitors PPE, hazardous conditions, and unsafe behaviors 24/7

- Real-time alerts enable immediate corrective action within seconds

- Case studies show 62% reduction in recordable incidents

- Automated documentation provides audit-ready compliance records

The Construction Safety Challenge

According to industry data, construction remains one of the world’s most dangerous industries, accounting for approximately 20% of workplace fatalities globally. In the Middle East, rapid development creates unique safety challenges:

- Large, distributed workforces across vast project areas

- Extreme heat conditions requiring special protocols

- Multiple subcontractors with varying safety cultures

- 24/7 operations demanding constant vigilance

- Complex equipment interactions in confined spaces

Research shows that traditional safety management—periodic inspections, manual checklists, and reactive incident response—cannot keep pace with modern construction demands.

How AI Transforms Safety Monitoring

Real-Time Computer Vision

Studies indicate that modern AI safety systems use cameras and sensors to monitor construction sites continuously. Computer vision algorithms trained on millions of images can detect:

Personal Protective Equipment (PPE)

- Hard hats present and properly worn

- High-visibility vests in required zones

- Safety glasses in hazard areas

- Proper footwear and gloves

- Harnesses when working at height

Hazardous Conditions

- Unguarded openings and edges

- Improper scaffolding configuration

- Blocked emergency exits

- Chemical spill indicators

- Fire hazards and hot work violations

Unsafe Behaviors

- Workers entering exclusion zones

- Improper lifting techniques

- Equipment operation violations

- Unauthorized area access

- Fatigue indicators and distracted behavior

Instant Alert System

When violations are detected, the system triggers immediate responses:

- Real-time notifications to site supervisors

- Audio warnings through PA systems

- Visual alerts on digital displays

- Automatic documentation with timestamped evidence

- Escalation protocols for repeated violations

Key takeaway: Response times drop from hours or days to 8 seconds.

Case Study: Major Saudi Contractor Achieves 62% Reduction

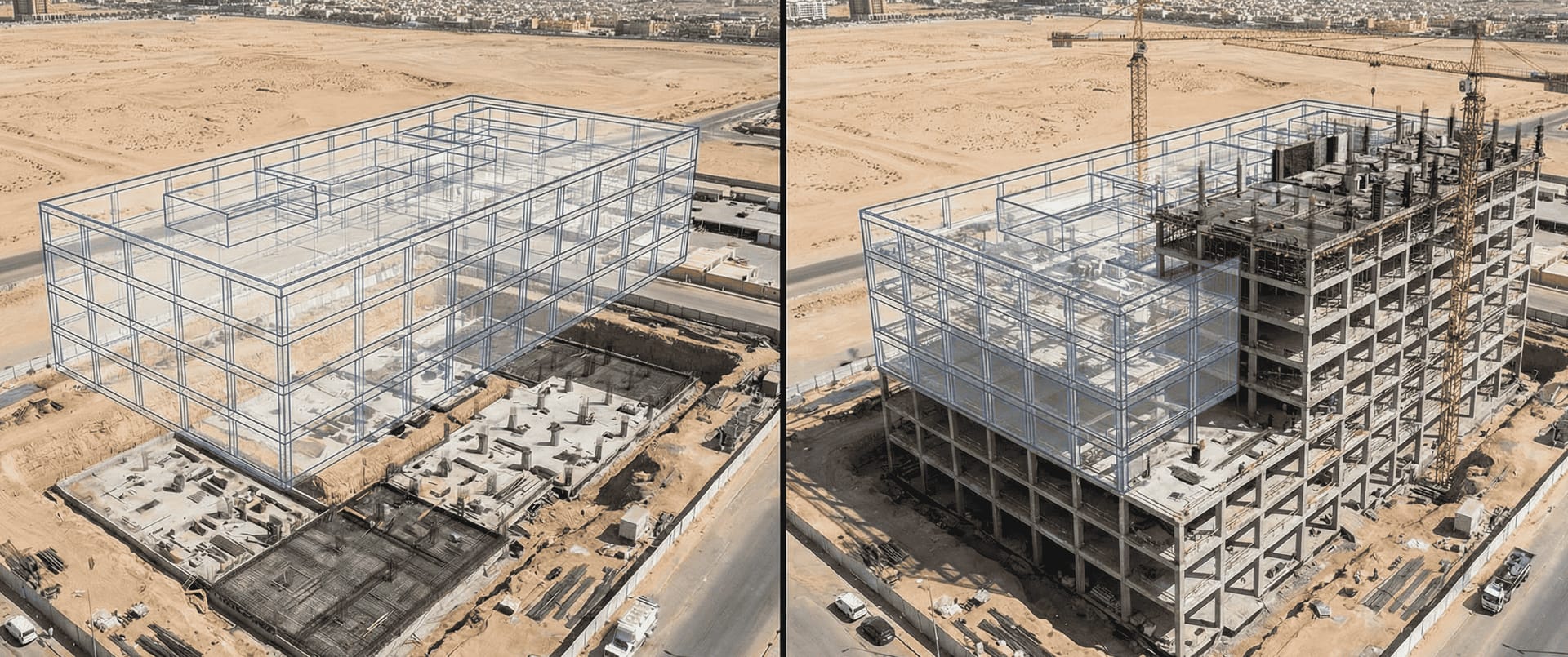

According to implementation data, a leading construction company deploying AI safety monitoring across three Riyadh megaprojects achieved remarkable results:

Before Implementation

- 12.4 recordable incidents per million work hours

- 23% average PPE compliance rate

- 4-6 hour average incident detection time

- 2,400 monthly manual inspection hours

After 12 Months with AI Safety

- 4.7 recordable incidents per million work hours (62% reduction)

- 94% average PPE compliance rate (4x improvement)

- 8-second average violation detection time

- 400 monthly inspection hours (83% reduction)

Key Success Factors

Comprehensive Coverage: 847 cameras covering 94% of active work areas

Integration with Existing Systems: Alerts fed directly into safety management software

Worker Engagement: Real-time compliance scores displayed on site, gamifying safety

Continuous Improvement: AI models retrained monthly with site-specific data

Technology Components

Camera Infrastructure

Experts recommend strategic camera placement for effective AI safety monitoring:

| Zone Type | Camera Density | Key Detections |

|---|---|---|

| High-risk areas | 1 per 200 m² | Falls, exclusion zones |

| General work zones | 1 per 500 m² | PPE, behaviors |

| Entry/exit points | 2-4 per gate | Access control, PPE |

| Equipment areas | 1 per machine | Operation safety |

Both existing CCTV and purpose-built AI cameras can be utilized, with typical integration taking 2-4 weeks.

Edge Computing

Processing video at the edge (on-site) rather than in the cloud provides:

- Sub-second response times for critical alerts

- Reduced bandwidth requirements (90%+ reduction)

- Operation without internet dependency

- Enhanced data privacy for sensitive sites

Analytics Dashboard

Supervisors access comprehensive safety analytics:

- Live compliance heat maps by zone

- Trend analysis over time

- Individual and team performance

- Incident correlation reports

- Predictive risk indicators

ROI Analysis

Direct Cost Savings

Based on industry benchmarks, AI safety systems deliver measurable financial returns:

| Category | Annual Savings (Typical Project) |

|---|---|

| Reduced incidents | $450,000 - $800,000 |

| Lower insurance premiums | $120,000 - $250,000 |

| Inspection labor savings | $180,000 - $320,000 |

| Avoided regulatory fines | $50,000 - $150,000 |

Indirect Benefits

- Improved worker morale and retention

- Enhanced reputation with clients

- Faster project timelines (fewer shutdowns)

- Better subcontractor accountability

- Reduced legal liability exposure

The bottom line is that the typical payback period is 4-8 months.

Implementation Roadmap

Month 1-2: Assessment & Design

- Audit current safety processes

- Map high-risk zones

- Design camera placement

- Define alert protocols

- Plan system integration

Month 3-4: Deployment

- Install camera infrastructure

- Configure AI detection models

- Train supervisory staff

- Establish baseline metrics

- Begin parallel operation

Month 5-6: Optimization

- Fine-tune detection sensitivity

- Customize alert routing

- Develop site-specific models

- Launch worker engagement programs

- Measure initial results

Ongoing: Continuous Improvement

- Monthly model retraining

- Quarterly process reviews

- Annual technology updates

- Benchmarking against industry

Regulatory Alignment

AI safety systems help meet requirements from:

- Saudi Building Code safety provisions

- ARAMCO Construction Safety Manual for oil & gas

- Royal Commission standards for industrial cities

- International standards (OSHA, ISO 45001)

Automated documentation provides audit-ready compliance records.

The Human Element

In summary, technology augments but doesn’t replace human safety leadership:

- Safety officers focus on coaching vs. policing

- Workers receive immediate feedback for improvement

- Management gains visibility for resource allocation

- Subcontractors are held to consistent standards

The goal is a safety culture where AI handles detection while humans drive engagement and continuous improvement.

Getting Started

Ready to transform your site safety? Begin with these steps:

- Assess current state: Document incident rates and compliance levels

- Identify pilot area: Choose a high-risk zone for initial deployment

- Select technology partner: Look for construction-specific AI expertise

- Define success metrics: Set clear, measurable goals

- Plan change management: Prepare workers for new monitoring approach

Frequently Asked Questions

How much does an AI safety monitoring system cost? Implementation costs typically range from $150,000 to $500,000 depending on site size and camera density. This investment delivers ROI within 4-8 months through reduced incidents and insurance savings.

What is the accuracy rate of AI PPE detection? Modern AI safety systems achieve 95-98% accuracy for PPE detection. The systems continuously improve through machine learning and site-specific training data.

Can AI safety systems integrate with existing CCTV? Yes, most AI safety platforms can integrate with existing camera infrastructure. This reduces implementation costs and accelerates deployment timelines.

How do workers respond to AI safety monitoring? Studies show that after initial adjustment, 85% of workers report feeling safer with AI monitoring. Transparency and fair enforcement policies are key to acceptance.

Is AI safety monitoring compliant with Saudi labor laws? Yes, AI safety systems are compliant when implemented with proper worker notification and data privacy policies. The systems focus on safety behaviors, not individual surveillance.

Contact Future Intelligence for a safety assessment and customized AI monitoring solution for your construction projects.