The Digital Twin Revolution

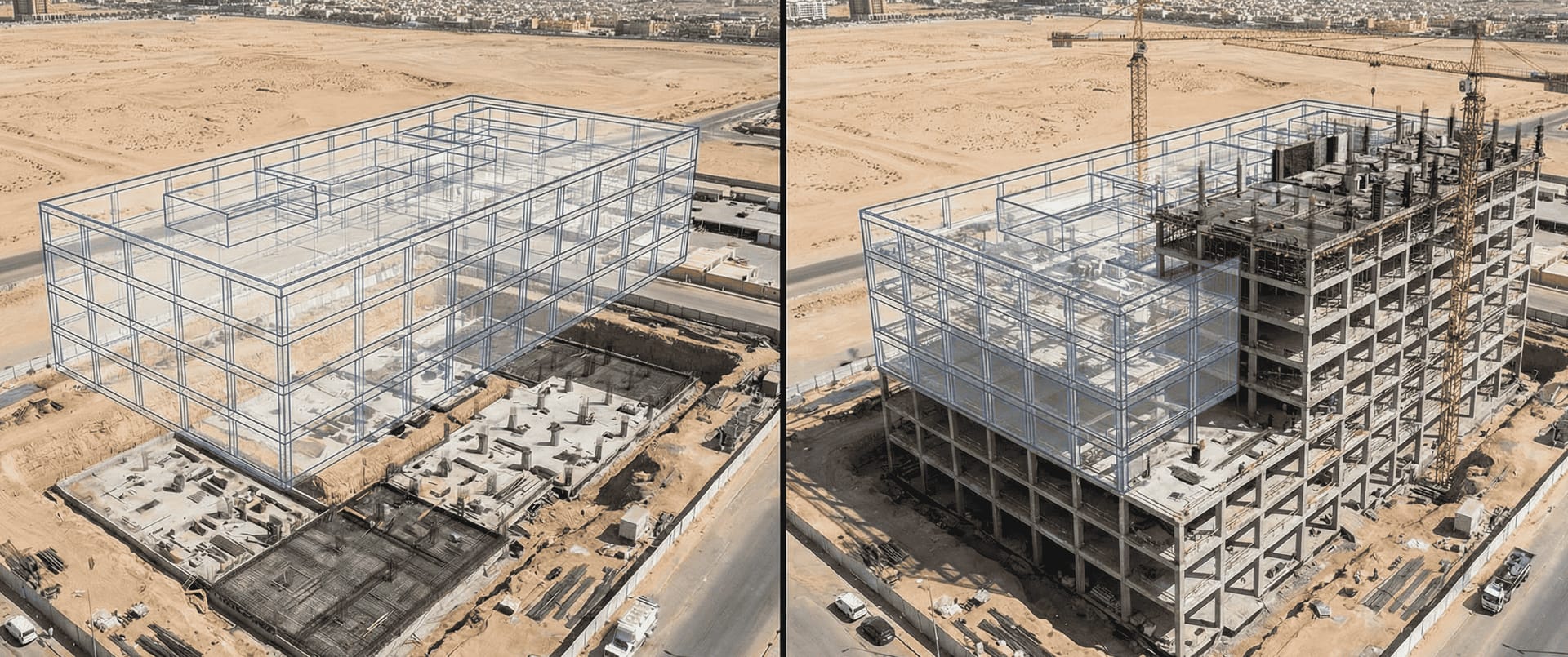

Construction is entering a new era where physical sites have digital counterparts that update in real-time. This digital twin approach enables:

- Instant comparison of as-built vs. as-designed

- Precise progress measurement without manual surveys

- Clash detection before problems reach the field

- Visual documentation for all stakeholders

- Historical records of every construction phase

Understanding 3D Capture Technologies

Photogrammetry

Photogrammetry creates 3D models from overlapping photographs:

How It Works

- Drones capture hundreds of images with precise GPS tags

- Software identifies common points across images

- Algorithms calculate 3D positions of each point

- Dense point clouds reconstruct surface geometry

- Textures from photos create realistic visualizations

Best For

- Large outdoor areas

- Terrain and earthwork volumes

- Building exteriors and roofs

- Progress documentation

Accuracy: 1-3 cm with ground control points

LiDAR Scanning

LiDAR (Light Detection and Ranging) measures distances using laser pulses:

How It Works

- Scanner emits thousands of laser pulses per second

- Pulses reflect off surfaces back to sensor

- Time-of-flight calculations determine distance

- Millions of points create detailed 3D cloud

- Software processes raw data into usable models

Best For

- Interior spaces

- Complex structural elements

- As-built documentation

- Quality assurance measurements

Accuracy: 2-5 mm for terrestrial scanners

Hybrid Approaches

Modern workflows combine both technologies:

| Project Phase | Primary Method | Secondary Method |

|---|---|---|

| Site preparation | Drone photogrammetry | Ground LiDAR for utilities |

| Structure construction | Drone + ground photos | LiDAR for connections |

| MEP installation | Handheld LiDAR | Photos for documentation |

| Finishing | LiDAR for tolerances | Photos for visual records |

BIM Integration Workflow

Step 1: Design Model Preparation

Before field capture, prepare your BIM model:

- Export to open formats (IFC, RVT)

- Establish coordinate system matching site survey

- Define construction phases and milestones

- Create comparison views for each element type

- Set tolerance thresholds for deviation alerts

Step 2: Reality Capture

Execute field capture with consistency:

- Maintain regular capture schedule (weekly recommended)

- Use same flight paths and scanner positions

- Include control points for accuracy verification

- Capture during optimal lighting conditions

- Document any site conditions affecting data

Step 3: Data Processing

Transform raw capture into usable models:

- Point cloud registration and alignment

- Noise filtering and outlier removal

- Ground/object classification

- Surface mesh generation

- Coordinate transformation to project system

Step 4: Model Comparison

Overlay reality capture with design:

- Automatic alignment using reference points

- Deviation analysis with color mapping

- Element-by-element comparison

- Progress percentage calculation

- Clash and conflict identification

Step 5: Reporting & Action

Convert insights into decisions:

- Visual deviation reports with tolerances

- Progress updates for schedule systems

- RFIs generated for significant variances

- Change order documentation

- Stakeholder dashboard updates

Software Ecosystem

Capture & Processing

| Software | Specialty | Key Features |

|---|---|---|

| Pix4D | Photogrammetry | Excellent drone workflow |

| DJI Terra | Drone mapping | Native DJI integration |

| RealityCapture | Hybrid | Fast processing |

| FARO Scene | LiDAR | Comprehensive analysis |

| Leica Cyclone | LiDAR | Industry standard |

BIM Platforms

| Platform | Strengths | Integration |

|---|---|---|

| Autodesk Revit | Architecture/Structure | Native cloud sync |

| Bentley iTwin | Infrastructure | Digital twin focus |

| Trimble Connect | Collaboration | Multi-format support |

| Navisworks | Coordination | Clash detection |

Comparison & Analysis

- Verity - Automated progress tracking

- ClearEdge3D - Scan-to-BIM

- Avvir - AI-powered comparison

- OpenSpace - 360 photo integration

Real Project Impact

Infrastructure Megaproject Results

A major transportation project in the Gulf region implemented weekly drone mapping with BIM comparison:

Before 3D Integration

- Monthly manual surveys

- 2-week lag in progress data

- Disputes over completion percentages

- Rework from undetected deviations

After Implementation

- Weekly automated updates

- Same-day progress visibility

- Objective measurement for payments

- Early deviation detection (avg. 3 weeks earlier)

Quantified Benefits

- 34% reduction in rework costs

- 28% faster progress reporting

- 89% reduction in measurement disputes

- 4.2x ROI in first year

Implementation Considerations

Hardware Requirements

Drones

- RTK-enabled for survey-grade accuracy

- High-resolution camera (45+ MP)

- Obstacle avoidance for safety

- Long flight time for efficiency

LiDAR

- Terrestrial scanners for interiors

- Mobile mapping for corridors

- Drone-mounted for roofs/facades

- Handheld for tight spaces

Skill Development

Teams need training in:

- Drone piloting and flight planning

- Scanner operation and calibration

- Processing software workflows

- BIM comparison interpretation

- Report generation and communication

Organizational Change

Success requires:

- Clear ownership of 3D capture process

- Defined handoffs between field and office

- Integration with existing workflows

- Executive sponsorship for adoption

- Continuous improvement culture

Future Developments

Emerging capabilities include:

Automated Progress Recognition AI identifies completed elements automatically, eliminating manual comparison.

Real-Time Streaming 5G enables live 3D capture streaming to remote stakeholders.

Augmented Reality Overlay Field workers see BIM design overlaid on physical site through AR glasses.

Predictive Scheduling AI analyzes historical patterns to forecast completion dates.

Getting Started

Begin your 3D mapping journey:

- Audit current state: Document existing survey processes and BIM maturity

- Define use cases: Prioritize applications with highest ROI

- Select pilot project: Choose manageable scope for initial learning

- Build capability: Train team or engage specialist partner

- Measure and iterate: Track results and refine approach

Future Intelligence provides end-to-end 3D mapping and BIM integration services. Contact us for a demonstration on your project.